Practical & Durable Hydraulic Land Rollers in Shea-Oak Log

WE MANUFACTURE HYDRAULIC FOLDING LAND ROLLERS IN SHEA-OAK LOG

HYDRAULIC FOLDING LAND ROLLERS

If you need a roller that is suitable for towing whilst still being durable and functional, you need one of our hydraulic folding land rollers. This innovative piece of equipment is designed to fold in on itself for travelling between paddocks or other land that requires rolling. The machine can be further compacted for easy loading by removing the pull.

Main feature

The centre roller is the centre of the machine. This eliminates side drag when turning and takes most of the strain off the bearings and framework.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

MODEL 9.000 and MODEL 12.000

HYDRAULIC FOLDING LAND ROLLERS

If you need a roller that is suitable for towing whilst still being durable and functional, you need one of our hydraulic folding land rollers. This innovative piece of equipment is designed to fold in on itself for travelling between paddocks or other land that requires rolling. The machine can be further compacted for easy loading by removing the pull.

Main feature

The centre roller is the centre of the machine. This eliminates side drag when turning and takes most of the strain off the bearings and framework.

MODEL 9.000 Only

-

Description

This machine has been designed with safety, easy operation and flexibility for different ground contours. It is the ideal machine for the person with large acres that need rolling or large distances between paddocks to be rolled, as there is no manual folding or unfolding.

There are safety valves fitted to main fold cylinders that, in the event of a fractured or blown hydraulic hose during folding or unfolding, the wing roller will stay in the position it was when the problem occurred. This means the hose will need to be fixed or mended to shift the wing, as the safety valve takes over and holds it until the problem is rectified.

The roller drums have bung plugs, but do not need water or fluid filling for normal operation. Water will make rollers drag more on soft soil and will need to be drained out to fold and transport.

The main tow pull is unbolt able for minimising the size of the machine for transport. After the first few hours of work, these bolts should be checked for tightness as loose bolts create uneven stresses to the frame.

-

Features

The main feature of the machine is the positioning of the rollers.

Most machines for rolling have 2 rollers behind the centre roller which are trailing with a hinge point so they are individual. If these were to be put into a fixed beam roller, the centre of the 2 trailing rollers becomes the centre of the machine. This is the difference, or main feature of this machine.

-

Specifications

Frame rectangular hollow section (RHS).

Electric Resistance Welded (ERW) pipe drums 0.508 mm diameter x 12 mm wall.

Two 8” x 2 ½” hydraulic cylinders on carrier wheels.

2 wheels 8.25 x 16 radial ply truck tyres fitted.

Two 24” x 4” hydraulic cylinders with over centre valves fitted for folding.

Heavy duty bearings on 50.8 mm shafts (2”).

Bronze bushes and grease nipples on main frame working points.

Dry weight (i.e. no ballast) 2.5 ton approx. depending on barrel type.

MODEL 12.000 Only

Slide title

Write your caption hereButton

-

Description

This machine has been designed with safety and easy operation in mind. It is the ideal machine for the larger stones in areas that have been direct drilled. There is no manual folding or unfolding.

There are safety valves fitted to main fold cylinders that in the event of a fractured or blown hydraulic hose during folding or unfolding, the wing roller will stay in the position it was when the problem occurred. This means the hose will need to be fixed or mended to shift the wing, as the safety valve takes over and holds it until the problem is rectified.

The roller drums have bung plugs but do not need water or fluid filling for normal operation. Water will make rollers drag more on soft soil.

-

Features

There is a centre roller and 2 wing rollers in a fixed, but flexible position with 1 roller in front of the centre roller and 1 roller behind the centre roller. This leaves the centre roller as the centre of the machine.

Most machines for rolling have 2 rollers behind the centre roller which are trailing with a hinge point so they are individual.

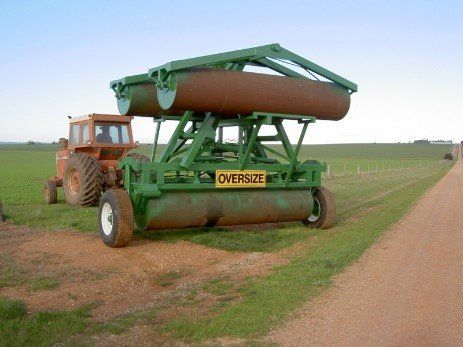

The main feature of this machine is the steering of the wing rollers to track behind (folded) or out (unfolded). The folding is all controlled from the tractor seat. The over head tow frame hitched to the lead roller close to the tractor keeps the machine length to a minimum when in transport position. The height of the frame above the rollers is for clearance on undulating surfaces.

-

Specifications

- Frame rectangular hollow section (RHS).

- Electric Resistance Welded (ERW) pipe drums from 0.720 mm to 0.810 mm diameter with wall thickness of 12 mm to 16 mm wall.

- Two 12” x 4” phasing hydraulic cylinders on carrier wheels.

- 2 wheels 385/65R22.5 super single radial ply truck tyres fitted.

- Two 24” x 4” and two 24” x 5” hydraulic cylinders working together with over centre valves fitted to do the folding.

- Heavy duty bearings on 60 mm shafts fitted on roller drums.

- Bronze bushes and grease nipples on main frame working points.

- Wing roller bushes are a bronze type.

- Dry weight (i.e. no ballast) 6.5 ton approx. depending on barrel type.

ELEPHANT ROLLER

These units are constructed with both ease of use and safety in mind to ensure that they perform well, even in the harshest environments. Features such as safety lock valves ensure that even in the event of a hydraulic hose failure, the wing roller concerned will stay fixed in position until a new hose is fitted.

-

Description

This elephant roller is the ideal machine for the larger stones in areas that have been direct drilled. There is no manual folding or unfolding involved in its operation.

There are safety valves fitted to main fold cylinders, so in the event of a fractured or blown hydraulic hose, the wing roller will stay in the same position as when the problem occurred. This means the hose will need to be fixed or mended to shift the wing as the safety valve takes over and holds it until the problem is rectified.

The roller drums have bung plugs, but do not need water or fluid filling for normal operation, as water will make rollers drag more on soft soil.

-

Features

Most machines designed have two rollers behind the centre roller. On this model, they trail with a hinge point, as they are individual.

The main feature of this machine is the steering of the wing rollers to track behind (folded) or out (unfolded). The folding is all controlled from the tractor seat. The overhead tow frame is hitched to the lead roller close to the tractor in order to keep the machine length to a minimum when in transport. The height of the frame above the rollers is for clearance on undulating surfaces.

PRODUCT WARRANTY:

MODEL 9.000, MODEL 12.000 AND ELEPHANT FOLDING

Leske Engineering Hydraulic Folding Land Rollers and Elephant Folding Land Rollers are warranted against all defects in material and workmanship, including all parts and accessories supplied with them as original equipment by the factory. This warranty is in force to the original user only for a period of 12 months. Failure due to abuse or abnormal use, is not covered.

Leske Engineering will replace, without charge, any original part that is returned to the factory and found to be defective under warranty terms. Transportation costs in making replacement are not covered in this warranty.

Leske Engineering makes no warranty to parts adjusted or manufactured by other manufacturers. Neither will we be liable for delay caused by defects for consequential damages, or for charges or expenses of any part which has been repaired or altered outside of our own factory.

This warranty is effective to the original purchaser only.

Contact Information

Phone:

Email:

Address:

71 Wandel Rd Shea-Oak Log SA 5371

Fax: